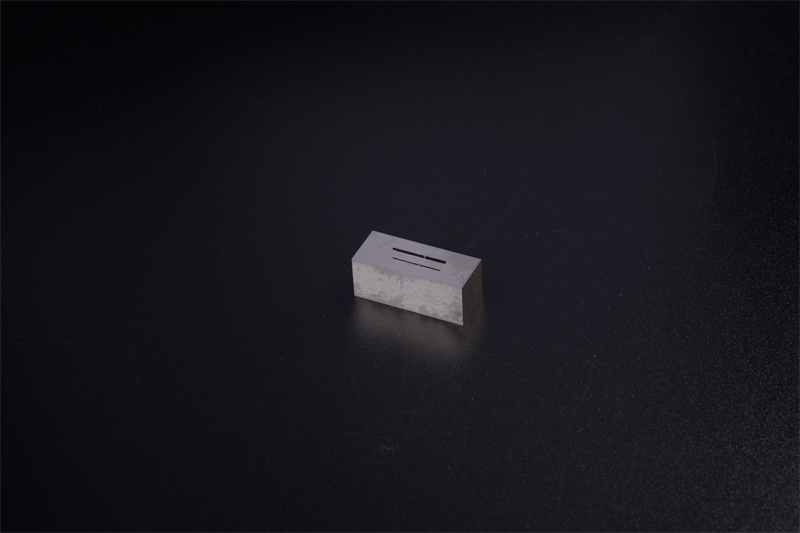

High precision oil wire cutting processing

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

By carefully controlling these factors, high precision oil wire cutting can achieve tolerances of up to +/- 0.002 mm, making it an ideal process for producing complex shapes with tight tolerances in materials such as steel, titanium, and other difficult-to-cut metals.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.