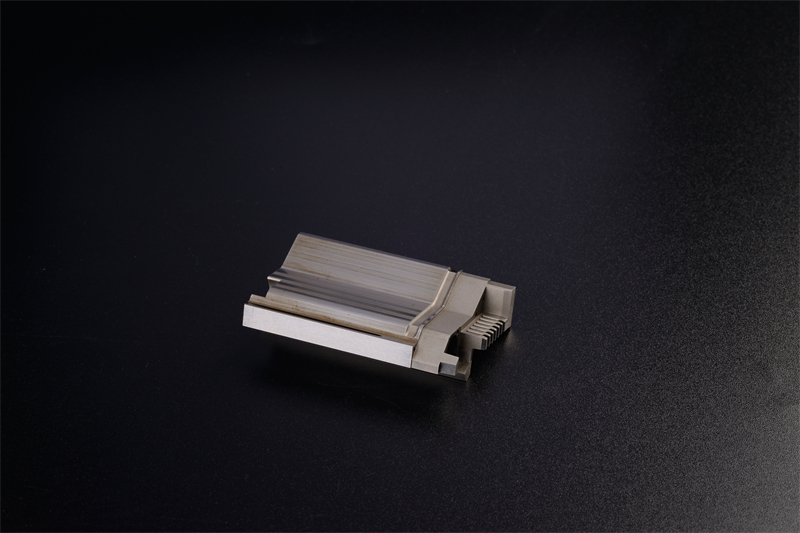

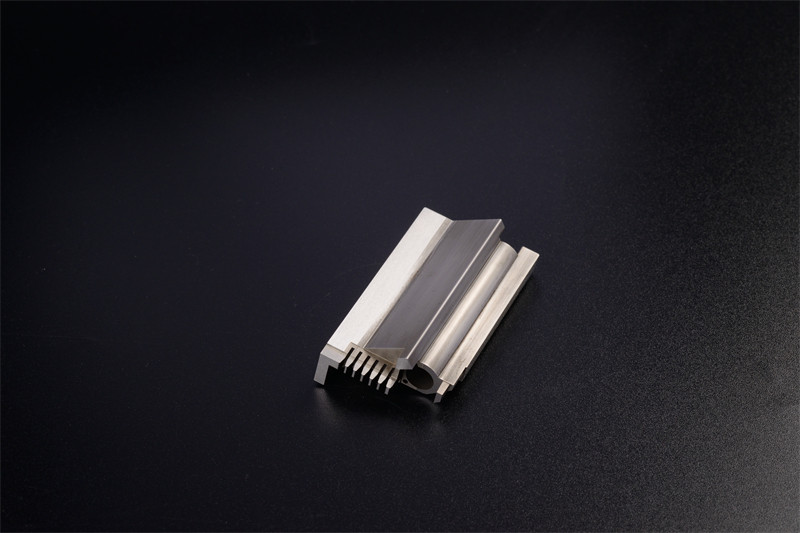

core and cavity in injection molding

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Model No.: ys18

Brand: yushun

Place Of Origin: China

Process: grinding

| Selling Units | : | Piece/Pieces |

Precision Electronic Consumer Moulds introduction

In injection molding, the core and cavity are two crucial components used to create a molded part. The core is a solid or hollow piece that forms the internal features of the part, while the cavity forms the external shape. Together, they create the desired shape of the final product.

During the injection molding process, molten plastic is injected into the cavity through a small opening called a gate. The plastic fills the cavity and the core creates any internal features of the part, such as holes, threads, or channels. Once the plastic has cooled and solidified, the mold is opened and the part is ejected.

The design of the core and cavity is critical to the success of the injection molding process. They must be precisely machined and aligned to ensure that the final part is accurate and free of defects. Factors like material type, wall thickness, and part geometry can all impact the design of the core and cavity.

Precision Electronic Parts Mold Processing display

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.